Our first experience with using foam on the exterior of a structure, besides using it to insulate our poured concrete foundations, was during 2005, when we built our first Timberpeg, Post & Beam home.

We had the choice of implementing one of two different methods. The first method is what’s referred to as “wrap and strap”. This method relies on the use of multiple layers of 4’x8′ foil-faced, isocyanurate foam panels, 4’x8′ sheets of plywood and 1×4 pine strapping.

This method provides an excellent thermal boundary, while leaving the beauty of the timber-frame joinery fully exposed at the interior of the home.

The “wrap and strap” method helps to hold down materials costs, but due to the fact that it requires multiple trips around the structure, in order to install each layer, it requires more labor than the second method of using SIP panels to enclose the frame.

We choose the “wrap and strap” method, because of the material cost savings, but after taking those multiple “trips” around the house, we vowed to try the SIP option on our next Timberpeg post & beam project and we did just that.

Our experience has shown that the SIP panels speed the process and provide higher levels of air-tightness and strength.

It was obvious to us that SIP panels were the perfect way to create a strong, air-tight, robust thermal boundary for our Timberpeg projects, but we realized that some of our clients might not be interested in a timber frames structure to go along with the SIP’s.

We immediately became interested it bringing this building envelope system to our all of our clients. Folks that might not be interested in a beautiful post & beam frame, but wanted a home that was safe, durable and energy-efficient.

We did our homework and researched the different SIP panel companies. We were looking for a company that had the best system, had a great reputation for customer satisfaction and wasn’t too far from our home range.

We found Enercept to be the best of the SIP panel companies.

Their commitment to quality and service is second to none. It is a real pleasure to work with people who share our values and our commitment to helping people save energy and our environment. At that time Enercept had been in business for over 25 years and had a great track record.

In our previous post, we talked about the challenges we face in educating consumers and SIP’s fall under the category of the unknowns.

According to the Structural Insulated Panel Association, (SIPA)

SIP panels were invented at the Forest Products Laboratory (FPL) in the mid 1930’s.

Some of the earliest examples of SIP construction can be found in the Usonian homes, designed by visionary architect and early adopter, Frank Lloyd Wright.

It was one of Wright’s student’s, Alden B. Dow, son of Dow Chemical founder, that was the first to use foam between the panel skins.

That was in 1951. Now, you know.

SIP’s have been around for quite a while, but public awareness of this killer-app building envelope technology has gone almost unheard of… Until now.

Think about that last scolding hot coffee or chocolate that came in a styrofoam cup. You had 1/8 of an inch of foam, between your hand and the hot liquid.

Now, think about a wall system with 5-1/2″ or 7-1/2″ of foam in your walls and 9-1/2″ or 12″ of foam in your roof system. Are you catching on?

SIP homes are very energy-efficient. They are also very air-tight.

Did I mention quiet? SIP homes are also very quiet. The sound deadening properties of SIP panels are excellent.

Another benefit of building with SIP’s is the construction time line. We’re able to get projects under-roof in record time. The last two SIP homes that we built were in the 1800 square foot range and each was under-roof within 4 days.

SIP homes are also very strong, due to the nature of the construction of a SIP panel and the shear strength inherent with its design. SIP homes are 2-1/2 times stronger than typically built homes. There are many reports of SIP homes surviving earth quakes and tornadoes, worldwide.

As you can see, there are huge benefits to building with SIP’s.

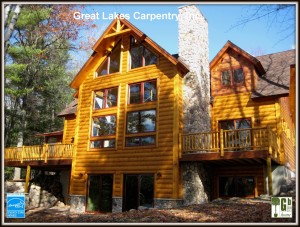

We at Great Lakes Carpentry believe that using SIP panels for our building envelopes makes perfect. We consider them to be the wave of the future.

The small amount of extra costs to build using SIP’s is recovered very early on, after which our clients realize very meaningful savings on the costs to operate their homes, for the life of the home.

One would think that cutting edge home building technology like this would be part of the conversation, when considering a new home. This is not the case.

We continue to encounter folks that don’t have a clue about this great way to build. Our biggest hurdle lies in educating the customer.

In most cases, once we show our prospects this system, they have a eureka moment. They get it! Because it’s so obvious.

Who wouldn’t want to save 40% to 60% on their energy costs?

We refer to our most recent SIP home as “The Energy Sipper”, because of the fact that is sparingly “SIP’s” energy.

We used Alpen High Performance windows, as they are the perfect fit for this type of building envelope.

We are very proud of the fact that we achieved stellar performance levels for the home. We achieved Passive House air-tightness standards, which are the most stringent energy design criteria in the building industry and we achieved a HERS score (home energy rating system) of 37. The HERS rating is fast becoming the industry standard for calculating the efficiency of new homes. Similar to miles per gallon. We strive to reach the lowest number possible.

Net-zero energy homes are on the horizon and we’re anxious to get the opportunity to build our first in the near future.

Great Lakes Carpentry specializes in building what we refer to as “Future Proof” homes. SIP’s are a big part of our strategy.

As always, our goal is to help educate the public about the benefits to building energy-efficient new homes and remodeling projects.

If you find this post educational and you believe in building homes that are part of the solution and not the problem, forward this post to a fiend.

Together, we can help drive the paradigm shift to building responsibly.

We love to talk about energy efficiency and building science. If you have any questions or are interested in building a future-proof home, contact us today.

www.greatlakescarpentry.com